The EAC certification of industrial machines and equipment is conducted in accordance with the regulations of Technical Regulations (TR CU/EAEU).

The aim of the regulations is to ensure the safety and quality of industrial machines, equipment, and installations in EAEU states. Certification is a mandatory measure, and compliance with the minimum requirements of Technical Regulations is monitored by the state.

EAC Certification for Industrial Facilities

The EAC approval for industrial machines and equipment is carried out in accordance with the regulations of Technical Regulations of the EAEU states. Several Technical Regulations (TR CU) are relevant for the EAC certification of industrial machines, equipment, and installations.

Typically, the following Technical Regulations are applied:

- 004/2011 TR CU - Certification of Low Voltage Equipment

- 010/2011 TR CU - Certification of Machines and Equipment

- 012/2011 TR CU - Certification of ATEX Equipment and Ex Equipment

- 016/2011 TR CU - Certification of Gas-Powered Machines and Equipment

- 020/2011 TR CU - Certification of Electromagnetic Compatibility

- 032/2013 TR CU - Certification of Pressure Equipment and Pressure Vessels

- 037/2016 TR EAEU - Certification of Hazardous Substances

The EAC approval process consists of several steps:

- Step: Product Examination

- Step: Product Classification

- Step: Examination and Production Audit

- Step: Issuance of EAC Approval

- Step: Monitoring and Inspection Control

The process of mandatory EAC certification for industrial machines, equipment, and installations depends on operational production processes and the type of delivery of industrial facilities. Typically, in addition to the mandatory EAC certification, voluntary certification of industrial safety must also be conducted.

Certificate acc. TR CU 004/2011 and TR CU 020/2011

The EAC certification according to the regulations of Technical Regulations TR CU 004/2011 and TR CU 020/2011 generally concerns the EAC certification of control cabinets, electrical distribution boards, and control systems of industrial facilities, machines, and equipment.

The control cabinets receive, measure, and distribute electrical power within the industrial facility. The switch and control cabinets are often delivered as ready-to-install units.

The control cabinets are subject to EAC certification according to the regulations of TR CU 004/2011 and TR CU 020/2011 for direct current of 75 to 1500 volts and alternating current of 50 to 1000 volts. Electrical control cabinets operating at high voltage or medium voltage are certified according to the GOST standards and TR CU standards.

Certification of Measuring Instruments and Devices

The EAC certification of measuring instruments and measuring devices in Russia is conducted in accordance with the regulations of Order N1081 - Metrological Approval of the Ministry of Industry and Trade of the Russian Federation dated November 30, 2009.

Additionally, measuring instruments and measuring devices are subject to EAC conformity confirmation in the form of EAC declaration according to the Technical Regulations TR CU 004/2011 - Safety of Low Voltage Equipment and TR CU 020/2011 - Electromagnetic Compatibility.

Furthermore, it is possible that measuring instruments are manufactured in explosion-proof versions. In this case, the measuring instruments are subject to the regulations TR CU 012/2011 - Ex Equipment and TR EAEU 043/2017 - Safety of Fire Protection Systems.

Certificate acc. to TR CU 010/2011 - Machinery Directive

The EAC certification of machines, equipment, and installations is carried out in accordance with the regulations of the Technical Regulation TR CU 010/2011 - Safety of Machines and Equipment.

The Machinery Directive applies to most machines and installations from various industrial sectors, with exceptions for: aircraft, spacecraft, and railway trains.

The conformity confirmation according to TR CU 010/2011 can be carried out in the form of EAC certification. The selection of the approval procedure is product-specific and is prescribed by the regulations of TR CU 010/2011.

In most cases, in addition to TR CU 010/2011, other regulations such as TR CU 004/2011 - Safety of Low Voltage Equipment, TR CU 020/2011 - Electromagnetic Compatibility, and TR CU 012/2011 - ATEX Directive are also applied.

Certificate according to TR CU 012/2011 - Ex Equipment

The EAC certification for ATEX devices is conducted in accordance with the regulations of the regulation TR CU 012/2011 - Equipment for Explosive Atmospheres. The certification of ATEX equipment is a mandatory measure and is controlled before import into the economic area of the EAEU states.

ATEX devices must be specifically marked with an Ex symbol. For the EAC certification of ATEX devices, additional documents such as explosion hazard assessment are required. The EAC EX marking must also be recorded in the documentation.

ATEX devices are categorized based on application areas, explosion zones, temperature classes, and explosion protection levels. Explosion protection is further divided based on explosion hazards and has its own Ex classification types.

Each explosion type is marked with a letter: a, b, c; these letters must be present on the product marking and in the documentation, for example, Exa or Exb.

For the approval of Ex devices, only certification is provided; there are no declaration options for approval according to the regulations of TR CU 012/2011.

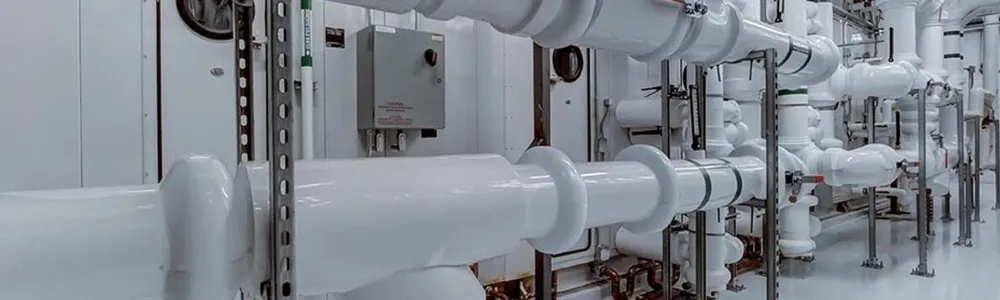

Certificate acc. to TR CU 032/2013 - Pressure Equipment

The EAC certification for pressure equipment and pressure vessels is conducted in accordance with the safety requirements of the Technical Regulation TR CU 032/2013 of the EAWU states.

For the approval of pressure equipment, in addition to the classic accompanying documents, such as operating instructions or safety assessments, additional documents and records such as strength calculations and pressure vessel passports must be created.

Necessary EAC Operational Documents

Depending on the regulation, various accompanying documents are required for certification:

- Detailed product description

- Description of the area of application

- Information about the manufacturer and importer

- Operating instructions and safety assessments

- Strength calculations and safety certificates

- Risk analysis, circuit diagrams, and welding certificates

- Safety data sheets and explosion hazard assessments

- Certificates for the quality management system

- Pressure vessel passport and technical passport

- Certificates for materials and components

- Acceptance protocols and test protocols

- Qualifications certificates for personnel

EAC Marking of Machines and Equipment

For all EAC certified or EAC declared machines, equipment, and installations, there is an EAC marking obligation according to the regulations of the EAEU states. Thus, the certified or declared facilities must be marked with the EAC conformity mark.

The EAC marking confirms EAC conformity with the technical safety requirements of the Technical Regulations of the Eurasian Economic Union (TR CU/EAEU).

The requirements for EAC marking according to the regulations of technical standards of the Eurasian Economic Union were established in the decision of the Commission of the Eurasian Economic Union N711. The EAC marking of industrial machines, equipment, and installations is a mandatory prerequisite for access to the EAC market.

Production Audit for Machines and Equipment

For the EAC certification of industrial machines, equipment, and installations, in certain cases, a mandatory EAC production audit of the manufacturer's production facility is prescribed according to the Technical Regulations of the Eurasian Economic Union.

A production audit for EAC certification is typically required for the EAC approval of series production after one year. The EAC audit is conducted by an accredited certification service provider at the manufacturer's production facilities. Production processes and conditions are analyzed and verified.

Based on the production audit, the assessment of the quality and safety of industrial machines, equipment, and installations is conducted. The conduct of the production audit is carried out according to the GOST regulations, GOST-R 54293-2010 - Production Audit for EAC Certification.

Inspection Control for Machines and Equipment

Depending on the directive, individual machines, equipment, and installations are subject to annual inspection control for EAC certification. For most facilities and machines, the inspection control is conducted as a formal document review.

During the annual EAC inspection control, it is verified whether the product is properly marked with the EAC marking and whether the product continues to meet the technical safety requirements of the directives.

An inspection control is a continuous certification and is a prerequisite for maintaining the approval. Annual inspection controls are only required for certification of series production after one year.

Validity and Costs of EAC Certification

The EAC certification or EAC declaration is conducted either contract-related (partial delivery) or in series (series production). For contract-related deliveries, a one-time EAC approval is conducted.

For series deliveries, an EAC approval for series production is conducted. The EAC certification for series production can be conducted for 1 to 5 years.

The costs of EAC certification for industrial facilities consist of several factors: the regulations of the directives, the number of required tests, the design of the facilities, as well as whether all source documents are available.